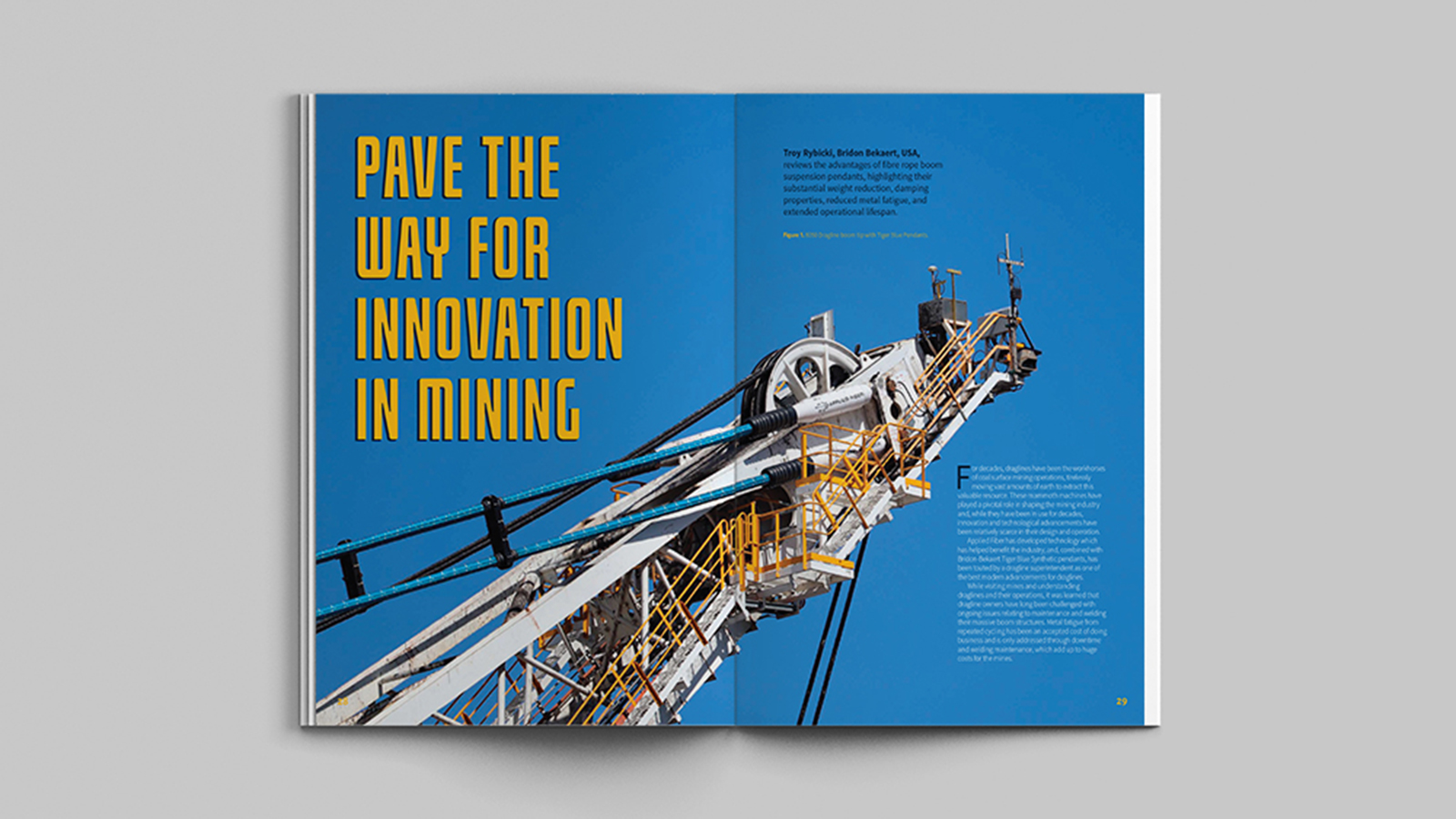

For nearly 100 years, heavy steel wire rope pendants were the only product available to support the massive weight of dragline and shovel booms. However, with a focus on improvement, Applied Fiber installed its first set of fibre dragline main pendants over 4 years ago on a Marion 8200 Dragline at Cloud Peak Energy, and the pendants are proving to have more benefits than initially planned. It is the driving reason why the company, now called Navajo Transitional Energy Co. NTEC, converted its dragline fleet to fibre pendants.

“The Applied Fiber pendants are a true step change in dragline technology. We converted a Marion 8200 in 2016,an 8200 in 2017 and a BE1570 in 2018 – all of which have nearly eliminated fatigue cracks and welding while smoothing out the machine operation,” said Wade Steiger, NTEC. The company’s advanced termination technology for fibre ropes enables the use of fibre for boom support pendants by providing a robust termination/end fitting on length matched fibre pendants. The connection removes wear at the end points and maximises the performance of a protected/armoured rope in this rugged mining application. The switch to fibre reduces weight aloft and peak shock loads and provides damping of vibration, which in turn reduces metal fatigue and the cracking that the equipment experiences over its life. The industry is noticing too. Visitors can see the difference from a distance and operators appreciate how much it quietens the machine down. The pendants do not jump rope’ like the steel pendants do, something which significantly reduces motion and wear throughout the machine. The vibration is also greatly reduced and can be felt throughout the equipment. “One of our operators went from having numb hands at the end of a shift to having no issues – the difference both in the cab and outside the machine is very noticeable. Putting a low-mass dampener into the boom makes all the difference,” noted Steiger.

The pendants are available for Marion, Bucyrus and Page draglines and Caterpillar and Komatsu electric rope shovels. While each machine and mine operation is unique, the effects of fatigue and vibration manifest itself into welding costs and machine and component downtime and ultimately, reduced pendant life. NTEC is running Marion 8200 and Bucyrus 1570 draglines and with the fibre installed are seeing numerous benefits, including an increase in capacity and a reduced workload on the machine.

“On the 1570, the dragline is running much smoother with significantly less fatigue. We would typically see regular cracks in boom nodules #8, #10 and #14, creating 1 – 2 weeks downtime a year. Since installing fibre pendants 2 years ago, we have yet to have cracks in this region. We estimate that we gained 1–2 weeks production in the first year of operation alone with the same in the second year,” commented Steiger.

NTEC is running three machines with a combined use spanning 9 years without fatigue cracks and welding. It is a remarkable feat, especially considering the company increased RSL on two of the machines and have plans to increase the 1570 bucket by 2 yd3. “NTEC has seen a substantial return on investment,” said Jim Pumphrey, VP Industrial Products for Applied Fiber. “While they initially purchased the pendants to increase machine capacity, the benefits to maintenance and reduction in cracking on the boom exceeded expectations. Their draglines are moving more payload while running smoother,with less stress overall.”

Vibration and damping

A key to the improved performance is the increased damping that fibre pendants provide over steel. Mine operators are experiencing the difference when they operate the machines, but as always want more information and support on how to further quantify the difference. “We know that fibre rope vs steel rope reduces peak shock loads by over 50% in comparative drop tests. Additionally,our clients requested test data on the damping properties of the pendants for their equipment,” explained Paul Badeau, VP Sales for Applied Fiber. A vibration and damping comparison between steel and fibre was performed in Applied Fiber’s manufacturing facility just outside of Tallahassee, Florida, US. The test compared steel pendant strand vibration against similar fibre pendant strands. Both specimens were axially loaded in tension on the company’s horizontal Instron tensile test bed. Utilizing diagnostic tools and software, Plymon Vibration Consultants performed third party testing to provide data analysis and comparative observation. Plymon provides companies with knowledge to assist in building predictive maintenance schedules for heavy machinery and guidance on improving reliability of key systems.The physical test placed accelerometers along the length of the fibre rope and steel wire strand. A calibrated impact hammer was utilized to apply equal force to both specimens. Measurements were then captured to measure how the fibre and steel behave.

The results were impressive: the fibre showed 10 – 20 times more damping in these tests. The fibre absorbs this energy as it materially dampens the impact load applied. That data shows how fibre dampens vibration as compared to steel.

“We routinely work with and measure vibration on steel machines, turbines and shafts to help us better predict replacement and maintenance cycles for critical components,” said Allen Plymon, Plymon Vibration Consultants. “I have never worked with this fibre material before and was amazed with its damping properties. Vibration is a large contributor to fatigue and failure in the systems we analyse. It is clear from these results that the fibre rivals some of the best materials to mitigate industrial vibration and damage to equipment and machines.” “We are thrilled to have this data to further support what operators have been telling us about the performance,” added Badeau. “While we set out to design a product that was lighter weight and would allow users to add capacity and extend life of the pendants, this data supports that the pendants also provides a much needed damper in the load path. It is like adding a shock absorber to the boom and provides benefits for both draglines and, even more importantly, electric rope shovels.”

Electric rope shovels used in coal and other surface mines around the world see substantial fatigue and

abuse during their service lives. Metal parts fatigue and wear out; booms, dipper sticks, gantry and revolving frame components require welding crews to repair cracking and fatigue as a part of regular maintenance routine. Adding more steel or just fixing the cracks is not always the best solution. A preventive maintenance approach with the switch to lightweight weight damping pendants (like those offered by the company) reduces the fatigue and vibration that leads to much of this routine wear and tear. It also acts as a big cost saver when down time can be reduced.

Boom Jacking

Another large contributor to shovel breakdown and maintenance issues is ‘boom jacking’. Boom jacking is one of the more violent events that a rope shovel experiences in operation and occurs when the pendants supporting the boom go slack as a result of the boom being driven upward by the dipper. When the shovel reengages, the boom drops freely, slamming downward and severely shock loading the pendant cables and system overall.

While no one wants to boom jack the shovel, the forces created when this occurs are substantial. Drop testing has proven that peak shock loads are reduced up to 50% when fibre is used vs steel. This translates to significantly less impact/damage on the shovel in the occurrence of boom jacking when fibre pendants are installed. An operator of a 4100 shovel said they noticed the difference in the operating smoothness of the shovel when rotating with full load over to a haul truck.

Fibre pendants perform 100 times better in tension-tension fatigue and will last 2 times longer than the existing steel pendants. “Every time we lower a boom, it is a risk event – reducing a risk event is a big positive for our company,” said a Director Asset Manager of a large mining company. Reducing risk and increasing returns is the key factor for operators to make the conversion to synthetic. The fibre pendants made from Dyneema® DM20 fibre are proven and tested at Applied Fiber’s manufacturing facility. All the cables are proof loaded and measured at tension on the company’s test bed, handling proof loads of up to 500 t.

“Applied Fiber’s pendant adoption is accelerating now with years of proven success on draglines and shovels (Figure 7). Additionally, our innovative inspection and monitoring technology coupled with increased safety factors facilitates the mine’s transition away from steel pendants and the sometimes, unreliable steel inspection methodologies,” said Pumphrey.

Conclusion

The benefits:

- Longer life: better fatigue resistance and better tension-tension fatigue yields longer cable life.

- Production increase/maintenance benefit: lighter weight pendants allow for increases in payload and reductions in boom stress.

- Reduce shock peak loads: shovel boom jacking peak loads reduced up to 50%.

- Increased damping/reduced vibration: less wear and fatigue on the machine and components.

- Safer handling/reduction of risk event: lighter and safer handling/skip a boom laydown (one of the mine’s major risk events).

- Operator ergonomics: smoother operation/less operator joy stick fatigue.

- Greater flexibility: reduced bend fatigue.

- Weight reduction: up to 2 – 3 times that over steel.

- Termination options: match existing connections or engineering team can design innovative alternative solutions.

- Faster installation and removal: easier than wire rope (no torque when pinning) saving time.

- Precise lengths/matched lengths: provides balanced loading on structure.

Advanced inspection and cable monitoring: Applied Fiber end terminations incorporate rope inspection and cable monitoring options that improve safety from day one of installation. The inherent benefits of synthetic ropes have been proven in numerous industries, providing additional safety and a return on investment. Operators want reliability and the ability to understand the rope performance. The company’s advanced inspection and monitoring features provide additional safety for this critical application.