Mooring Terminations for Offshore Renewables

Moorings for renewable power generation have challenges which differ from current offshore moorings. The scale of planned projects require volumes not currently available and concurrently with local content. Field data is critical both for the efficient operations of these systems as well as design optimization. The varied mooring conditions and system designs highly benefit from design flexibility. Applied Fiber’s technology addresses these challenges through a DNV certified process which delivers a highly configurable termination with reliability at scale anywhere in the world.

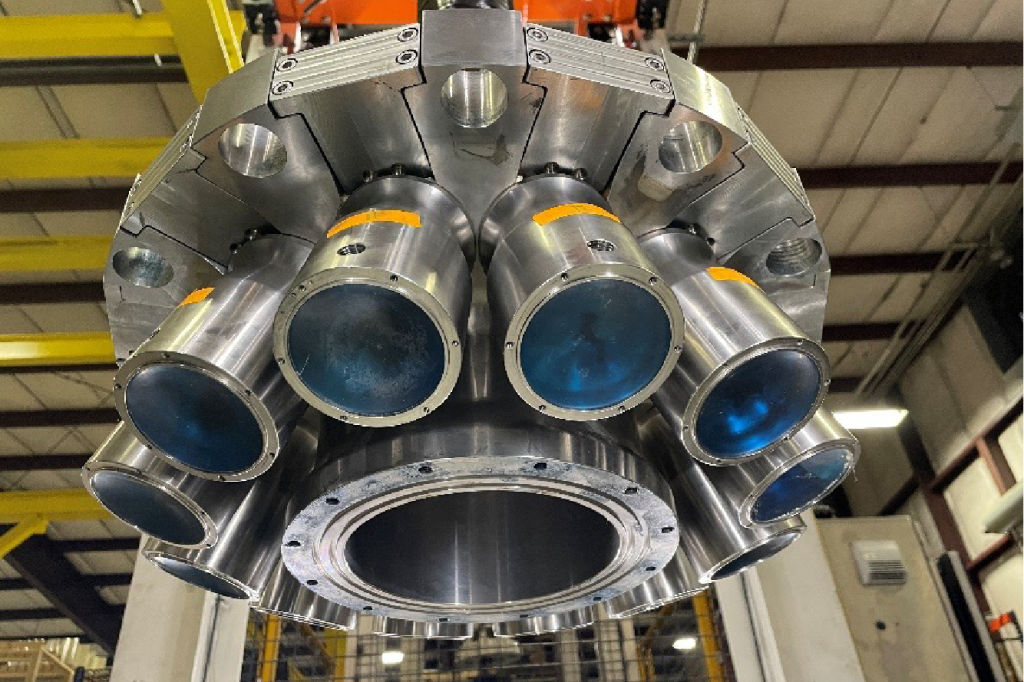

Semi-Automated Process

Applied Fiber’s termination process is certified by DNV and substantially reduces the variability inherent with manual splicing with no negative impact to performance. With our technology and equipment, termination process can take place anywhere in the world, addressing local content requirements while still delivering product performance, consistency and reliability.

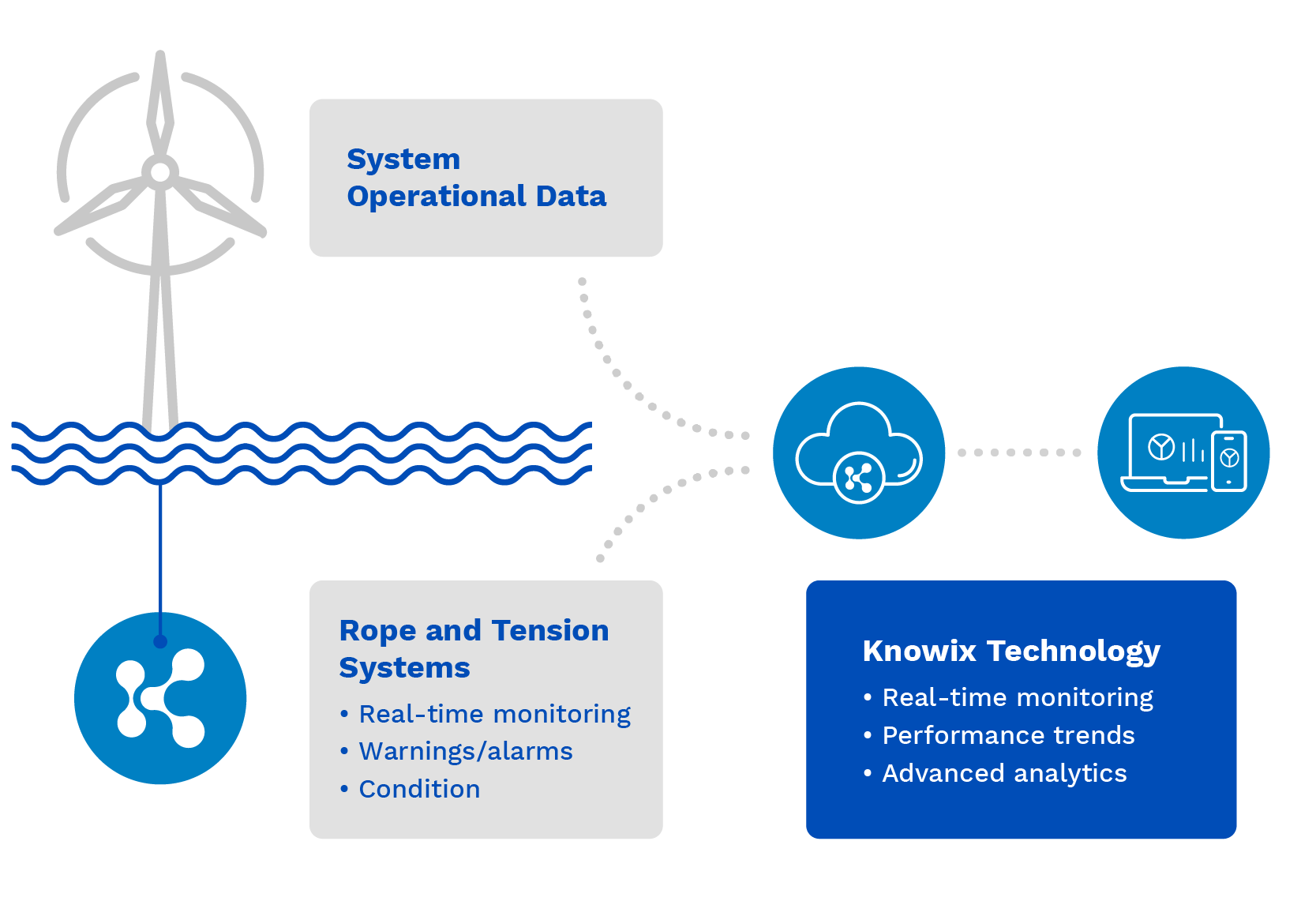

Intelligence

Applied Fiber’s terminations are an ideal measuring point for mooring line performance. Through its exclusive partnership with Knowix, Applied Fiber's smart terminations can deliver data on mooring line conditions and status. The incorporation of Knowix sensors into the termination does not impact the size of capabilities of the termination. Through the Knowix platform large numbers of mooring assets can be managed from anywhere in the world.

Highly Configurable

The Applied Fiber termination can be designed to incorporate additional functionality such as quick connect/disconnect, hand-off connections or ROV interfaces. The termination can connect directly with components that splice ropes cannot thus facilitating efficient pre-loading and installation of the mooring line. The termination can also isolate the mooring line from motions at the connection points reducing abrasion and fatigue.