Renewable Moorings Present New Challenges...

Applied Fiber Versatile Connections...

and System Intelligence...

Improve Safety and Reliability... Reduce Lifetime Cost

Offshore Mooring Systems

Renewable energy mooring challenges:

Reduction of unit cost of energy produced is key to establishing viable solutions. Material and design boundaries must be pushed, however mooring failure is unacceptable. The mooring solution must be optimized to provide long term cost of ownership reduction.

Considerations for any mooring solution:

- Guaranteed connection and disconnection to the anchor and top side structure

- Efficient and safe installation and removal process

- Minimal mooring components

- Use of data to optimize system, maximize life, minimize cost, while managing risk

Applied Fiber integrated IIoT offers a step change in risk management and optimization:

- Maximizing product life while minimizing scheduled maintenance

- Improving safety with performance assurance

- Intervention only required based on data

- Reducing cost and waste

The predicted growth in demand presents a serious challenge in how to manage the entire product lifecycle cost including the need to manage the product at the end of useful life to minimize the impact on the environment.

Reducing our environmental impact and assuring supply chain stability were key drivers in deciding to license our technology to manufacturers around the world, enabling complete production of the final mooring product at source, removing excess product miles and costs.

Applied Fiber Licensed Technology Provides Mooring System Advantage

System Intelligence:

- Real time measurement and monitoring of the mooring at a sub-rope level

- Make critical mooring rope components visible

- Eliminate traditional blind (non-inspectable) subsea fiber rope connection points

- Both digital and event-triggered field diagnostic inspection capability

Engineered Design Optimization:

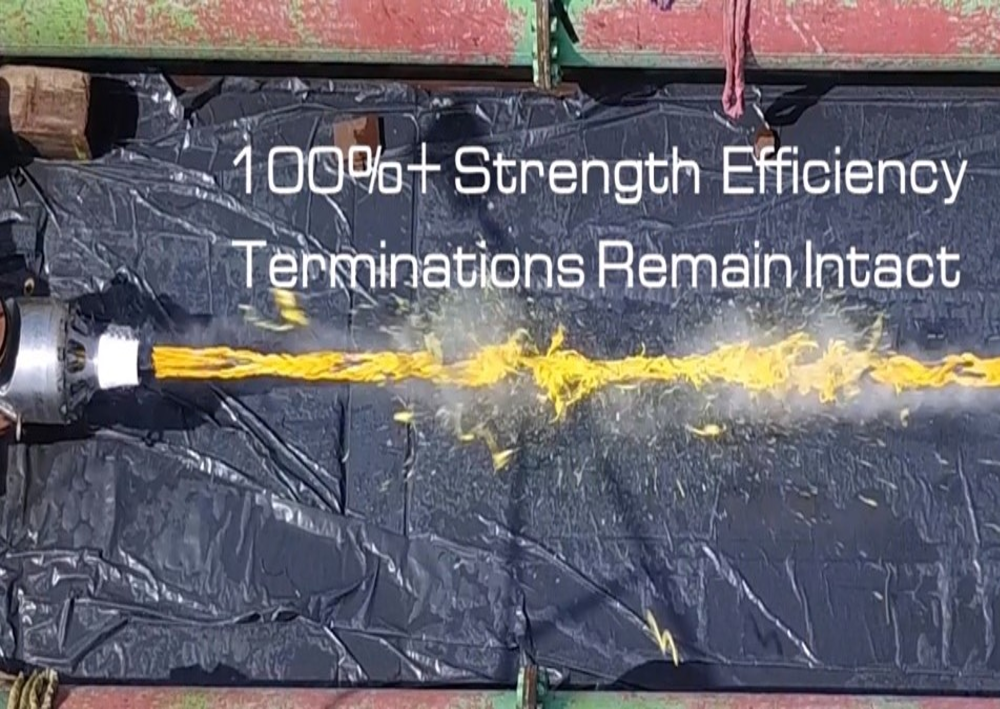

- Optimize mooring rope design based on advanced socketing capability = Less rope material and less cost

- Platform-to-Anchor system design flexibility – versatility of connections unlike any other option

- Precise, stable lengths for short tether applications such as TLP configurations

- Reduce connections and offshore handling complexity – improving installation time, safety, and cost.

Manufacturing Assurance:

- 18-year track record of successful mission critical applications

- Automated and traceable manufacturing processing equipment – terminated at any location, same QA.

- Available through licensed manufacturers – Improving supply chain stability, domestic content, logistics, and lead times.

Applied Fiber’s proven termination technologies allow for mooring system optimization while minimizing risk.

Contact Applied Fiber to learn more.