Dragline Main Boom Pendants

Applied Fiber combines critical systems expertise and proven termination technology to provide high performance dragline main boom pendants designed for safe and reliable long-term use. Purpose engineered main, lower, and intermediate boom pendants harness the inherent performance advantages of synthetic fiber over steel – significantly less weight with higher strength, dampening, and fatigue life. While fiber is more expensive than steel, the pendants have proven benefits that have consistently provided a solid return on investment.

Over Six Years of Performance Data on draglines in North America. Read the success story and testimonial here.

Fiber Pendants Outlast Steel

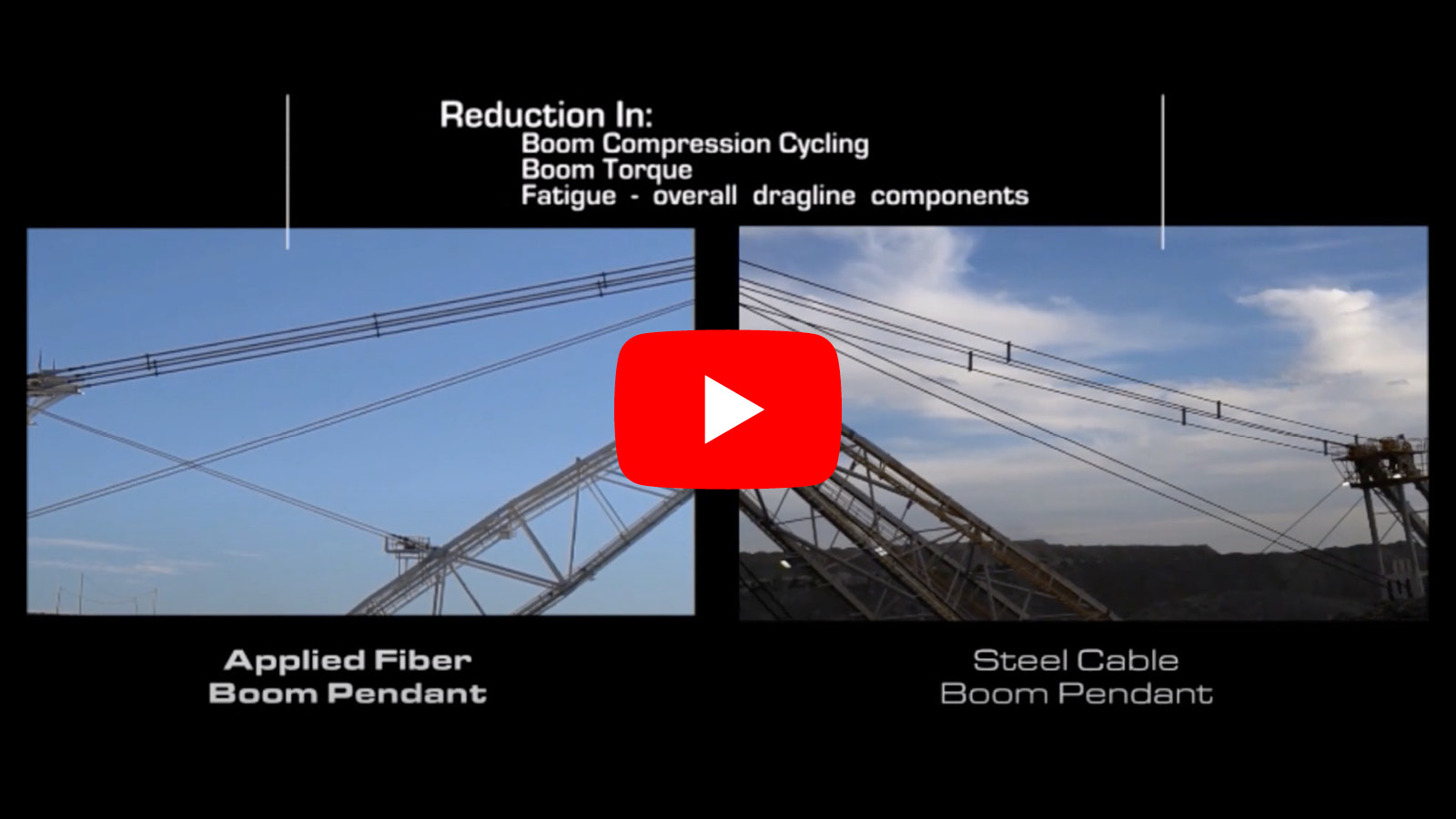

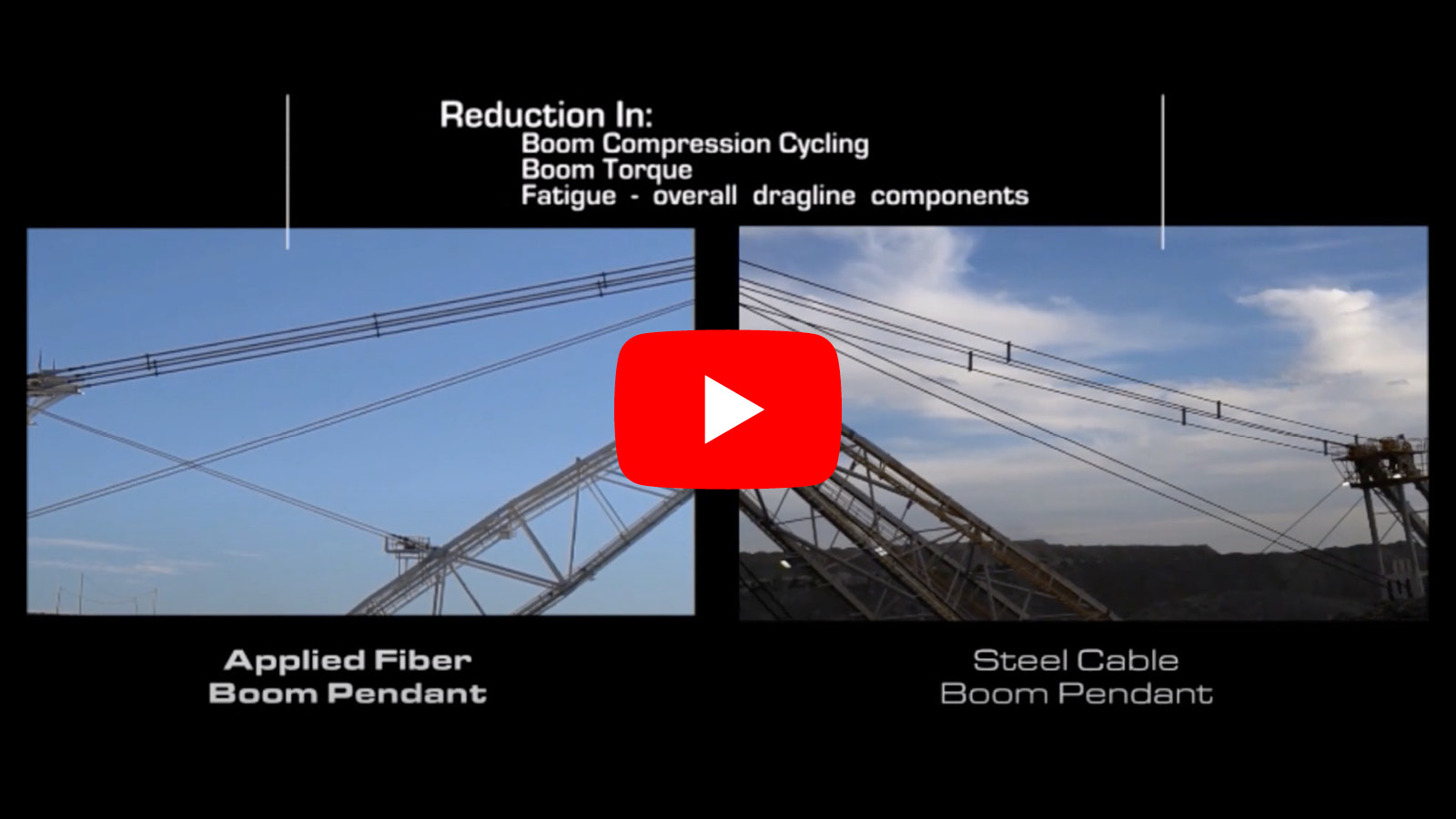

Steel vs. Synthetic Fiber Main Pendants on Dragline

Applied Fiber Dragline Synthetic Main Boom Pendants

Testimonial: Wade Steiger, Manager, Cloud Peak Energy

Steel vs. Synthetic Fiber Main Pendants on Dragline

Applied Fiber Dragline Synthetic Main Boom Pendants

Testimonial: Wade Steiger, Manager, Cloud Peak Energy

System Benefits

Demonstrated ROI – Easily Calculate Mine Return on Investment Applied Fiber has developed a ROI calculator that allows mine owners to directly input variable items relating to their equipment and mine site including: strip ratio, bucket capacity, cycle rates, pendant sizes, maintenance costs to see what their return on investment will be as a result of conversion.

Dramatic Weight Reduction - made with Dyneema® DM20 Fiber, the world’s strongest fiber™ which provides excellent strength to weight ratio.

Increased Payload Capacity Use the dramatic weight reduction to increase capacity or bucket size. Moving more material every cycle.

Extend Boom Life / Increase Pendant Lifespan Engineered synthetic cable systems have a fatigue life many times that of steel as proven in numerous critical offshore applications.

Extend Time Between Boom Lay Downs by pushing out a boom lay down the returns are substantial.

Reduce Boom Fatigue and Cracking / Less Welding

Fatigue Life up to 3X as Compared to Steel Wire mains reducing maintenance cost.

Provide up to 10X more dampening, quieting “jump rope effect” and related tension cycling – reducing boom fatigue. Reducing weight and shock reduces wear and tear on the system and mating components.

Reduce Maintenance Costs

Reduce Installation Costs

Increase Life of Dragline

Advanced Inspection and Cable Monitoring Applied Fiber Pendants include proven inspection and retirement criteria designed for critical systems. Several cable monitoring options are available.