Tendon Design & Manufacturing for Humanoid Robotics

Humanoids tendon-driven actuation systems operate in demanding environments where tendon performance is defined by:

High-cycle fatigue life in all load conditions

- Length stability addressing creep and elongation

- Compact packaging and micro terminations

Repeatability precision manufacturing

Scalability from pilots to automated production

Proven in Robonaut and prosthetics

Supported NASA Robonaut tendon development

Tendon cables for hand and foot prosthetics

Thousands of assemblies in service worldwide

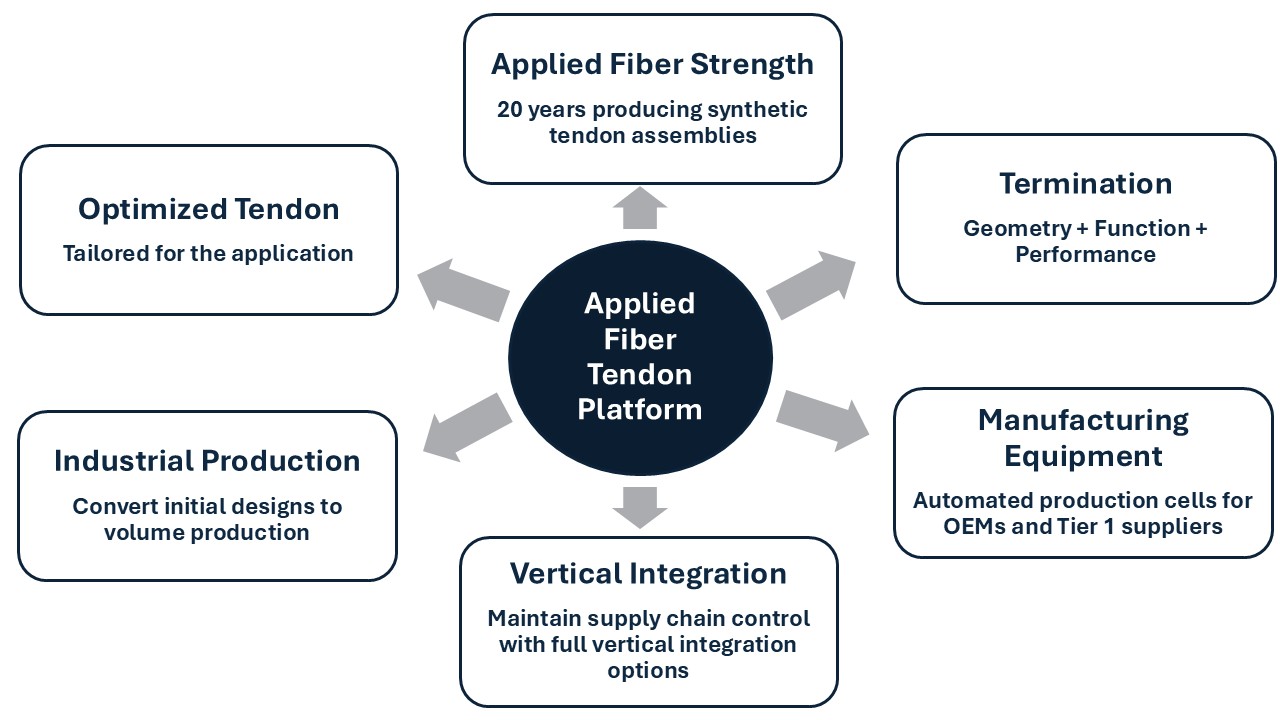

Applied Fiber’s tendon platform combines engineered fiber constructions, precision terminations and controlled manufacturing methods enabling customers to validate designs efficiently, progressing from early development through pilot builds to high volume production.

Scale and Supply Chain Control

A clear pilot-to-production pathway for tendon manufacturing

Vertical integration options from select components to complete in-house tendon manufacturing for OEMs

Automated and semi-automated production equipment to reduce variability

Consistency across builds - controlled processes

Scale readiness as the program matures

Supply chain and cost control

Contact Applied Fiber today to start a technical conversation.